It is an undeniable fact that computers have changed the landscape of every industry, and a clear example of this is the technology being used in CAD jewelry design.

At the outset, it seemed as though there was no way for the old world artisans’ skills to be replicated by computer assisted design. The thought that artistic skills used by master model makers could be assumed by computers in a mechanized world was absurd.

As a jeweler who has designed and created jewelry for over 40 years, I can attest to the inaccuracy of this way of thinking. It seems the one thing we did not take into consideration while believing this fairy tale was the element of human interaction. The computer did not replace the jeweler. It simply made it possible for artisans to express themselves with more clarity than ever before.

Having led an elite team of jewelry designers through the technological learning curve through the use of CAD jewelry design, we now find ourselves immersed in a world of seemingly endless possibilities.

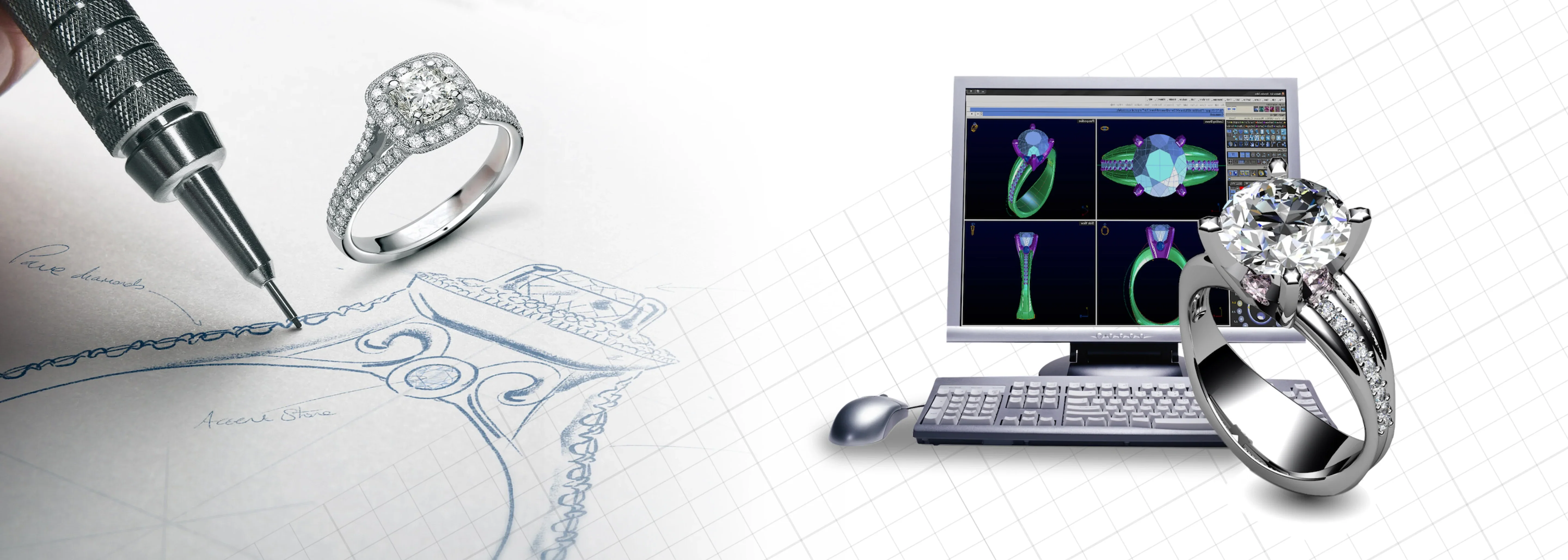

While CAD jewelry design does not replace the need for jewelers who cast, polish, solder and weld gold or platinum, or the setters who seat gemstones, it does make possible the creation of prototype models which can be rendered as three dimensional designs. Today’s jewelry sculptor uses a keyboard and mouse instead of files, spatulas, and wax pens to create his or her works. The work of these artisans still requires artistic vision, paired with the same knowledge of materials and understanding of jewelry fabrication procedures as his or her predecessors. Only the tools have changed.

Once created by hand as a wax carving, CAD jewelry designs are developed on computer screens by artisans using state-of-the-art equipment and software that metamorphose their thoughts and keystrokes into works of art. These works are then sent in the form of digital files to mills, printers, or growing machines where they will be transformed from data to a 3-D wax or resin form.

The three-dimensional form is then embedded in plaster investment, which will be placed in a furnace to incinerate the model. The investment containing the negative impression will be filled with molten gold or platinum by centrifugal or vacuum casting to precious metal that will be tooled and worked by skilled bench jewelers. The finished CAD jewelry design will move on to the jewelry polishing team to prepare it for diamond setting.